Cone gears

Conical gears are used to change the direction of rotation of the shafts. These types of gears include straight gears and spiral gears, but the helical gear type has less noise and vibration. If the direction of the right-hand conical gear is suitable for clockwise shafts and also left-handed conical gears are suitable for anti-clockwise shafts. The ratio used in this type of gears is 1: 2 to 2: 1.

Cone gears with straight teeth

Conical gears have a conical appearance and are used to transmit power between two intersecting axes. The simplest type of gear has a straight tooth. The extension of these teeth reaches the apex of the hypothetical cone. The process of making these teeth is easier and they do not create any trust force. On the other hand, the disadvantage of this type of teeth is that after heating, it is not possible to grind the teeth.

Straight teeth are made in two ways, “Gleason” and standard. In the Gleason method, the ends of the teeth have an inward curvature. Even if there are small errors in the alignment of the axles, these gears are able to withstand it. Straight teeth are commonly used in low-speed applications (less than two meters per second at ambient speed). Their main application is in machine tools, printing machines and car differentials. They are also rarely used to transport large forces.

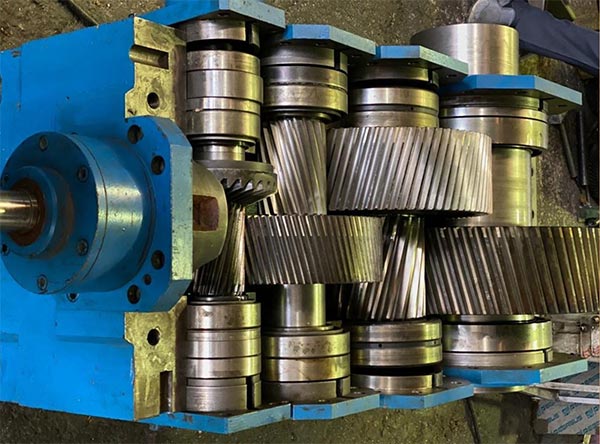

Conical gears with helical teeth

The teeth of this type of gear are in the form of helical curves. Unlike the straight type, these teeth engage slowly and evenly. Both Gleason and standard manufacturing methods are used in this model. But the Gleason type is more useful. In this type of gears, it is possible to grind the teeth after heating. This makes it possible to produce more precise gears.

Spiral gears

Screw gears are mainly used as reducing gears. The ratio of these gears is from 1: 1 to 4: 1. This type of gear is installed in such a way that screw gears can rotate the gear, but vice versa is not possible. These gears are more used in transport equipment and emergency braking system.

Spiral gears

Jahan Farz Industrial Group, a manufacturer of industrial gears, by providing experienced engineers and using the latest technology in the world, provides various services in the field of designing various types of gears.