Jahan Ferez Industrial Group is a manufacturer of various types of industrial gears, employing experienced engineers and using the latest technology in the world, providing various services in the field of designing various types of gears.

Relying on past experiences and current knowledge, this company has been able to present itself as a gear manufacturer in the country’s industry. Production and manufacture of gears required by industries and industrial companies such as spiral conical gears, helical gears, spiral gears, chisel gears, pinion crankshafts and coupling gears are on the company’s agenda.

The company’s activity is not limited to the production of gears. Gearbox design, gearbox manufacturing, Flander gearbox design and production, rolling machine gearbox and solar gearbox are among the activities of this company as a supplier of gearboxes and gears for steel and cement petrochemical factories, road construction and power plants.

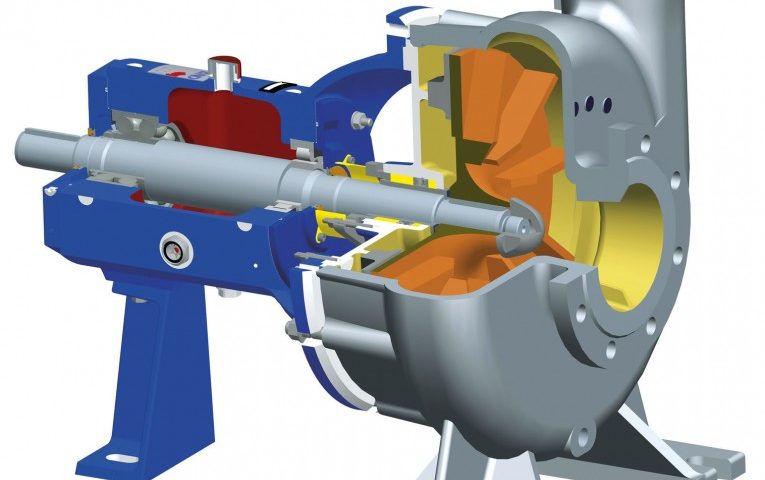

Jahan Farz, in addition to reviewing the design and construction, offers overhauls of gearboxes of industrial factories as one of the special services to industrial factories. These services are in line with industrial localization and supply of centrifugal pump parts, gearboxes and gear profile stones to In addition to solving the problems of factories, the process of repairing and maintaining their special parts will be improved.

Gear definition

Gears are one of the most widely used means of power transmission and movement. The mechanism of the gears is a system consisting of at least two gears that work in pairs. That is why it is called the gear mechanism. In terms of power transmission, the gear mechanism has one actuator gear and one or more to the smallest gear mechanism, the pinion and to the driven gear. Usually other gears are called wheels. Today, most machines in the industry have gears, and with the increasing development of the industry, gears have an undeniable role. The gears are designed and manufactured in various shapes according to the spatial position of the axes relative to each other, directing the rotational motion of one axis from the other to the other.

Classification of gears

Gears are classified depending on the position of the axles.

Figure a) Gears whose axes are in the same plane and parallel. Simple gears are helical, double helix and simple internal. Internal gears are also made in a helix. Too often, gears are produced with infinite radiation, which is called a comb gear. These gears are made in simple and spiral shapes

Figure b) Gears whose axes are located on one plane but intersect the other. These are conical gears, and as shown in Figure B, conical gears can also have simple, helical, truncated, and curved teeth.

Figure c) Gears whose axes are not on the same plane and are opposite to each other. They are spiral gears. The type of screw and screw (or wheel and screw) of this gear, whose axes are perpendicular to each other in space, has more applications in practice and includes different types. The type of their cylinders and the type of globoid are two examples of them (c).

Types of gears

Simple gears

These gears are the simplest type of gears, they have straight teeth and are parallel to the axis. To reduce the speed and increase the power, in many cases, a large number of them are put together. On parallel axes the direction of motion of one of them is opposite to the direction of motion of the other. If they want to move two engaged gears in the same direction, they put a third gear between them to become one for the direction of movement of the entry and exit. Simple gears, helical and truncated, are also called front gears.

It is cheap because of its easy construction and therefore has many applications in industry. For example, it is used in cookie and automatic clocks, washing machines, fans and samples of these. Their biggest drawback is the loud noise. Each time the gear of a gear touches the gear of a wheel, a small sound is produced by the collision, and when a large number of these gears come together, the sound becomes louder, to the point that even in the long run, this Collisions cause the teeth to break.

Spiral gears

The teeth of these gears are oblique and are angled with the rotating axis. When one of the gears rotates, the tips of the teeth first come in contact with each other, then gradually the two teeth engage, and this gradual engagement reduces the noise. Also, the gear mechanism works smoothly, the contact surface of the gear profiles is higher than that of a simple gear, and a large power transmission is performed. Such gears are widely used in the automotive industry.

Cone gears

Power transmission through these gears is possible at an angle of 90 degrees or less than 90 degrees or greater than 90 degrees, so they are considered the best gears for power transmission at the desired angle. Of course, in industry, they are often used with perpendicular axes. Their teeth are made on simple incomplete cones or spirals. These gears are widely used in gearboxes and especially differentials.

Snail gears and screw screws

These gears have a special place in the industry. If we want to make a big change in speed or power, we use this mechanism. The biggest interesting advantage of this mechanism is that the screw can screw in easily